The Measure of Real Adaptation!

"The right answer for the resilience of modern urban infrastructure."

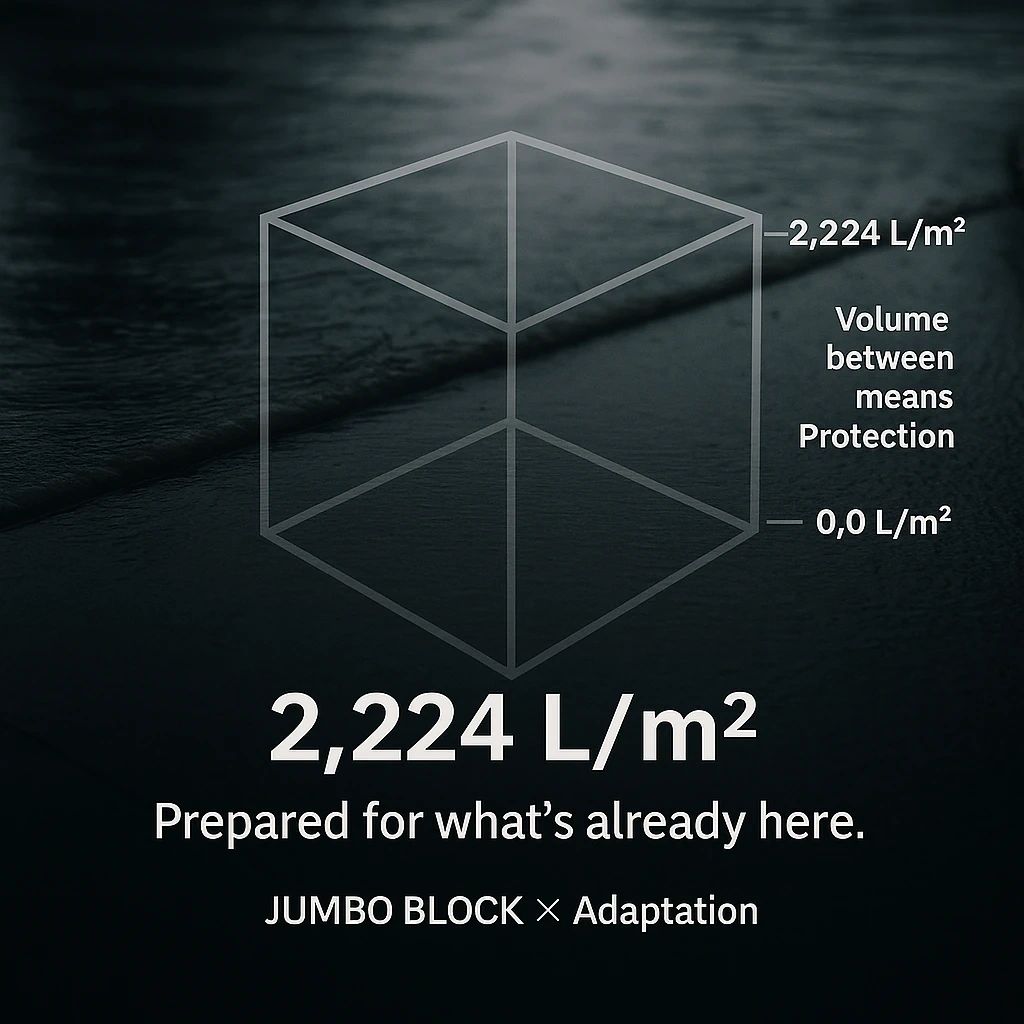

Every square meter of surface above a JUMBO BLOCK stores up to 2,224 litres of water — directly below ground level.

"Just volume, and strength. A grid of hollow giants, each holding 13.9 m³ of water."

JUMBO BLOCK Components

1️⃣ JUMBO BLOCK

The core of the system – a massive, hollow, load-bearing concrete module (2.5 m x 2.5 m x 2.5 m) with an impressive capacity to support up to 792 tonnes. This block is designed for underground installation, forming the backbone of a modular and scalable retention system.

2️⃣ Sedimentation and Filtration Inside the Block depending on configuration and project size

The built-in filtration system captures sediments and impurities within the JUMBO BLOCK itself. This design prevents clogging and extends the lifespan of the system, while maintaining a continuous water flow.

3️⃣ Heavy-Duty Cover Plate

The cover plate provides an ultra-strong, load-bearing surface above the JUMBO BLOCK. It enables heavy-duty applications like roads, airport runways, and industrial sites, while ensuring surface stability and protecting the system below.

A System of strength

4️⃣ Side Plate

Side plates are installed to enclose the JUMBO BLOCK modules on the sides, preventing lateral water movement and ensuring system integrity. They help stabilize the overall structure and protect against shifting forces.

5️⃣ Base Plate

The base plate provides a stable foundation for each JUMBO BLOCK, distributing the weight evenly and creating a secure, level base. This feature is essential for ensuring structural stability and longevity.

6️⃣ Sealing System

The sealing systems for JUMBO BLOCK provide durable, waterproof solutions for module connections. Using high-performance adhesives and sealants, they securely seal joints and connections, preventing water loss and optimizing retention efficiency. Their flexible, durable materials ensure long-term functionality under varying conditions.

JUMBO BLOCK Technical Data

JUMBO BLOCK Technical Data

Load Capacity

Class F 900 *

Block Size

2.5 m cube

Material

Proprietary high-performance concrete with CO₂-reduced formulation.

Capacity

13.9 m³ per block

Water column capacity

2,224 litres per m² of covered surface

Total system volume

Scalable by modular configuration.

Installation

Fast and immediately operational.

* Final load class depends on application and local requirements.

Key Features

- Underground water retention

- Heavy-duty capacity

- Modular & scalable

- Fast installation

- High water retention

- Sustainable

- Infrastructure-ready

- Long lifespan

- Multifunctional use

- Climate resilience

Versatile installation options

- Urban areas

- Industrial zones

- Transport infrastructure

- Agricultural land

- Natural environments

- Commercial and residential Developments

- Parks and recreational spaces

Sustainable

Sustainable

- Reduces surface sealing

- No plastic tanks or honeycombs

- Reusable & recyclable

- Protects soil and groundwater

- Minimizes surface runoff and flooding

Sedimentation and Filtration by AQUATO

Sedimentation and Filtration by AQUATO

Sedimentation and Filtration by AQUATO

Sedimentation

JUMBO BLOCK systems can be equipped with one or more sedimentation units that separate and retain solids from stormwater before it enters the storage volume.

The number and configuration of these units depend on the overall system size and application.

Filtration

The filtration units use multiple filter elements to remove pollutants such as organic compounds, heavy metals, mineral oils, and polycyclic aromatic hydrocarbons (PAHs).

They ensure that the stored water meets high environmental and quality standards.

Combined Sedimentation and Filtration System

In a combined setup, both processes are integrated into a single unit.

Rainwater passes through several stages — sedimentation, adsorption, filtration, and chemical precipitation — to achieve comprehensive purification.

Each installation is project-specific, adapted to the hydraulic and environmental requirements of the site.

Sealing by SABA

Sedimentation and Filtration by AQUATO

Sedimentation and Filtration by AQUATO

The sealing systems for JUMBO BLOCK are reliable, waterproof, and long-lasting solutions for module connections. Our high-performance adhesives and sealants of SABA, specifically engineered for the demanding conditions of rainwater management. They ensure a secure and durable seal for joints and connections, preventing water loss and optimizing the efficiency of retention systems. With a combination of flexible and highly durable materials, these sealing solutions guarantee long-term functionality, even under varying environmental and load conditions.

Exception

For infiltration systems, external sealing is not needed.

Planning

It is recommended to involve certified professionals during planning to ensure the sealing meets specific project requirements and guarantees optimal functionality.

Certified